Eco-Friendly Manufacturing Process

Our PVA films are manufactured with a unique low-energy process that recycles waste steam from a nearby power plant. This reduces our carbon footprint and production costs: what we save is passed on to our customers.

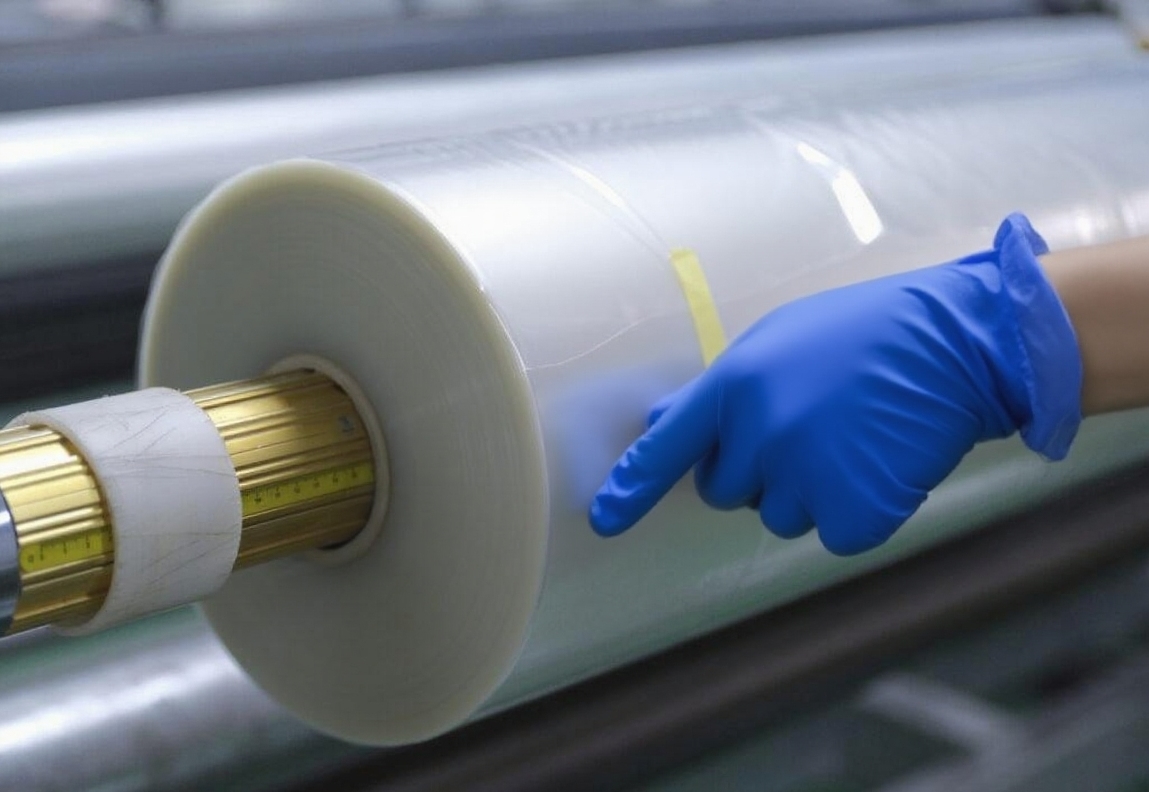

Multi-layer Drying Technology with Advanced Heat Recovery

Our innovative in-house system recycles piped-in waste steam efficiently, with an energy reuse rate of 80%. Combined with infra-red heating tech, it reduces our overall manufacturing energy costs by 50%. Uniform heat is key to high-quality PVA films.

Less For More: High Efficiency & Yield

High efficiency in delivery volumes with in-house engineered, high-speed production lines, delivering films up to 4X faster than other manufacturers

Locally Sourced & Developed

Locally sourced raw materials and in-house developed material formula means less reliance on import shipping, and up to 75% lower costs.

Environmentally Responsible Operations

Backed by official Environmental Impact Assessment (EIA) reports approved by government authorities.

20,000 Tons Annual Capacity

We are one out of a handful of manufacturers in the world able to deliver over 3,600 tons annually. Made possible with our 20 high-efficiency, energy-efficient manufacturing lines at our 30,000m² manufacturing plant.

Fully Biodegradable

Our PVA material is fully biodegradable. PVA is the only polymer that can used by bacteria as a carbon source, allowing it to degrade by 75% in 46 days.

No Microplastics

When PVA dissolves and degrades, it doesn't break down into microplastics. Instead, it’s broken down into simpler components like carbon dioxide and water.

Reduces Waste

As PVA is water-soluble and dissolves after use, it leaves no physical waste behind.

Sustainable & Recyclable

If recycled instead of biodegraded, the PVA’s material lifespan can last multiple cycles.